|

|

| |

|

Building Integrated Agriculture can provide more than just fresh,

local food. Integrating vegetation into buildings

can improve energy management, air quality, interior comfort and

worker productivity. With its high yields and efficient use of resources,

urban hydroponic food production also provides urban food security

and eases pressure on the environment from conventional agriculture.

As the planet becomes increasingly urbanized, and the density of

developed areas increases, the natural world is being displaced,

pressured and marginalized. The ground is a diminishing percentage

of the built area of a city, and it becomes more remote from people

as they live and work in ever-taller structures. In this context,

vertical surfaces are an untapped opportunity to bring nature into

the built environment. |

a vertical greenhouse

in a double skin office facade a vertical greenhouse

in a double skin office facade |

| |

|

Modern field agriculture is the largest consumer

of land and water on the planet, the source of most water pollution,

and the cause of 15% of the world’s greenhouse gas emissions. Three

major trends: increasing global population, movement of populations

to urban areas, and global warming, will increasingly strain the

global food system over the next half-century, leading to widespread

shortages of food, water and arable land by 2050. |

Crop Circles, Kansas

(NASA Earth Observatory) |

| |

|

Transportation and storage: Fresh vegetables come to the

city at a particularly high ecological price. In New York City, the average

supermarket item has traveled 2500 km to reach the consumer, and in the case

of fresh produce, this trip has to be made particularly quickly,

with refrigeration en route, even though well over 90% of the product

is simply water. Studies

have also shown that 40% of the ecological footprint of a city

is from food production and transport. |

transporting vegetables is

difficult because they are delicate, consist mostly of water, and need

refrigeration. |

| |

|

|

Solutions: These challenges – essentially, the need of humans for

sustenance, shelter and nature – are inherently linked and that therefore,

their solutions may also be linked, through direct integration of

food supply into the built environment. Growing crops on buildings

has the potential to confer a host of benefits including a reduced

environmental footprint, reduced transportation costs, greater food

security, enhanced energy management of the building envelope, and

perhaps most significantly, improved physical and psychological comfort

for building occupants.

|

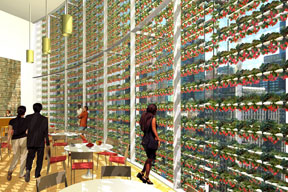

strawberries growing

in a cafe |

| |

|

|

Vertical farms have been proposed by our friend

and colleague Dickson Despommier and others as a solution to

this crisis. (see www.verticalfarm.com )

Our approach is somewhat different from the ambitious concept

of the standalone, all-food producing urban farm - more limited

and immediately practical. We’d like to integrate food production

into buildings, specifically growing hydroponic crops in building

envelopes, facades and roofs. As well as the benefits of food

production, this provides benefits

to the building and occupants through reduced energy costs and

connection to nature, and makes the best use of available solar

energy.

|

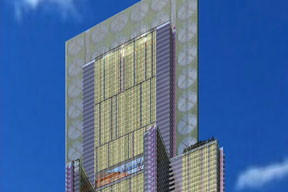

the 2020 tower with VIGs on part of the facades |

| |

|

|

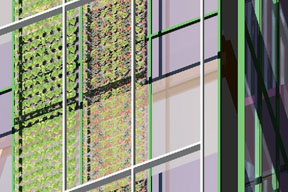

The Vertically Integrated Greenhouse (VIG) is a

highly productive, lightweight, modular, climatically responsive

vegetable culture system designed to be installed in the curtain

wall of a high rise building. The system is achievable with extant

technology and draws from modern advances in both hydroponic methods

and building design. The design was developed in 2007 by Kiss + Cathcart

with Arup, Engineers and Bright Farm Systems (www.brightfarmsystems.com). |

VIG on 2020 tower VIG on 2020 tower |

| |

|

|

Hydroponics, the culture of plants in water, is a commercially

common, well developed practice. It has been publicly demonstrated,

by commercial growers, and by New York Sunworks Science Barge in

Manhattan (link www.nysunworks.org)

that ecologically sensitive, recirculating hydroponics produces premium

quality vegetables and fruits using ten to twenty times less land

and five to ten times less water than conventional agriculture, while

eliminating chemical pesticides, fertilizer runoff, and carbon emissions

from farm machinery. |

hydroponic seedlings |

| |

|

|

Double Skin Facade: In the building sector, the

double skin facade (DSF) is an innovation which can substantially

reduces energy use and increase interior comfort in high rise buildings

by providing a second layer of glazing, typically on the southern

facade, creating a vertically continuous void space. A DSF provides

solar heat gain, buoyancy-driven cooling flows, protection for external

solar shades, and sound insulation. A DSF also enables opening windows,

a convenience that enhances personal comfort and local climate control,

but is unavailable on conventional high-rise facades due to wind

pressure and stack effect. Despite these advantages and a certain

popularity in Germany and other areas of Northern Europe, the DSF

still stands on the brink of widespread adoption but remains constrained

by economic concerns. |

VIG prototype by BrightFarm systems |

| |

|

|

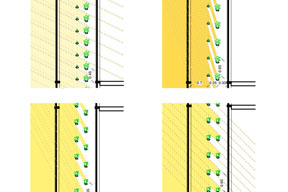

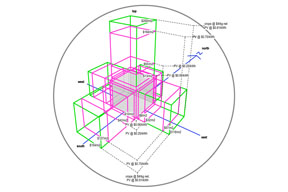

System Description: The Vertically Integrated Greenhouse design

integrates hydroponic food production into a DSF, for installation

on new high-rise buildings and potentially as a retrofit on existing

high-rise buildings with adequate southern exposure.

A south facing vertical facade at northern latitudes admits a fairly

even distribution of sunlight throughout the year. Solar radiation

is highest in winter, when produce prices peak.

Plants are grown on trays suspended by a simple cable system, and

all planting and harvesting occurs at the bottom level. Systems modules

can rise as high as 10 or 20 stories each. An adaptive control system

alters the angles between rows of plants in the manner of Venetian

blind, maximizing solar absorption diurnally and seasonally. |

VIG sections showing daylight control |

| |

|

|

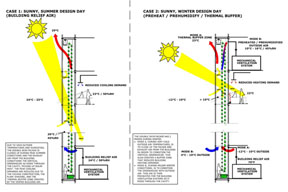

Integration with HVAC System: The VIG provides

the building designer with an additional tool for managing energy

demand and occupant comfort, through integration with the building’s

HVAC system. A wide number of potential operating modes exist, but

some of the most significant are illustrated in Arup’s diagram.

- In winter, the VIG is an effective solar capture device, warming

and insulating the glazed facade of the building. On winter nights,

exhaust air from the building can be ducted to the VIG to maintain

plant temperatures.

- In summer, the VIG shades the interior of the building, and provides

a source of fresh air to occupants with opening windows. The VIG

reduces solar heat gain by absorbing energy as latent heat, through

transpiration.

- The VIG also mitigates the urban heat island effect like a green

roof.

The integrated VIG / building system is complex but has a host of

benefits we have only begun to analyze and quantify, including carbon

dioxide / oxygen transfer and cleaning of the building air, possibly

allowing lower ventilation rates. |

integration of the VIG with building systems |

| |

|

|

Yields: We modeled the VIG on our hypothetical design, the 2020

tower, for a New York City location.

To deploy the VIG across a facade 60 m wide for 50 floors of the

tower would take 135 modules (2m wide, 1.5m deep and 40m high) producing

over 400 tons of crop annually, slightly exceeding the total fresh

vegetable consumption of all of the 3,000 tenants occupying those

floors.

Beyond the value of the produce, energy benefits and human productivity

benefits, the ecological value of local food production is

substantial.

Each of the 135 modules in this system would conserve 300 tons of

fresh water per year, avoid up to 3.75 tons of CO2 emissions, and replace 1/10th of a hectare

of cropland, reducing habitat impact and agricultural runoff. Finally, no chemical

pesticides will be necessary in the VIG.

featured projects > |

diagram showing the relative income from building surfaces used for PV generation or agriculture |

|

|

|